|

Far infrared type for home useCoffee Bean Roaster

『Hot air (drum) type roaster』

|

As mentioned earlier, we usually use hot air or drum roasters outside of

homes and some coffee shops. The only advantage of the drum type is that

the amount of beans roasted is large.

The structure of the hot air roaster is shown below. There are two types:

one that heats the air with a burner and then sends it to the drum, and

the other is a semi-hot air type that directly hits the drum with flames.

Both are also called drum type because they use a rotating drum to put

beans in. |

|

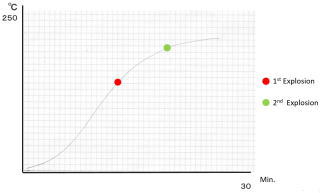

The graph below is the roasting profile showing the temperature change

from the start to the end of roasting process with the drum type.

In the drum type process, the temperature inside the kettle reaches to about 200 ℃ before the beans are put into the drum. When a large amount of beans at room temperature is added, the beans take a large amount of heat from the hot air. As a result, the temperature plummets from 200 ℃ to below 100 ℃.

Two things can be gaged from this graph. (1)The temperature on the graph is not that of the beans, but the air temperature in the kettle. (2)The temperatures inside the drum and the beans' surface reach to a high temperature of 200 ℃.

Two kinds of heat serve to heat the beans in the drum type: convection

and conduction. Convection heats air and water to a high temperature and

transfers heat to objects that contact the air and water. Heat moves from

the hot part to the cold area.

At first, the surface of the beans is heated with hot air, so that the

surface temperature is raised, and then the heat is transferred to the

core, which is the cold part.

The surface temperature of the beans becomes the same as the hot air temperature

relatively quickly. If they are the same, the surface temperature of the

beans will not rise any higher, the heat flow from the bean surface to

the core will disappear, and the temperature of the core will not rise.

As a result, even if the surface of the beans is charred, the core remains

raw. In other words, roasting spots occur. This is probably the reason

why the hot-air roasted beans seem to have thorns and the aftertaste also

has a sharp stimulus to me.

As mentioned earlier, there are three ways to transfer heat: conduction,

convection, and radiation. In conduction, heat is sequentially transferred

through adjacent objects. Convection is carried by fluids such as gases

and liquids. In conduction and convection, heat spreads from high to low

temperatures. If there is no temperature difference, heat transfer will

not occur. As for radiation, electromagnetic waves transfer heat. Far infrared

rays are one of the electromagnetic wavespt.

In the drum type, the above convection, that is, air is heated, the surface of the beans is heated with hot air, and the core of the beans is heated by conduction heat. The surface temperature of the beans becomes the same as the hot air temperature relatively quickly. If there is no temperature difference between the two, there will be no heat transfer from the hot air to the beans, consequently there will be no heat flow from the bean surface to the core. As a result, even if the surface of the beans is charred, the core remains raw. In other words, roasting spots occur. This is probably the reason why the hot-air roasted beans seem to have thorns to me, and the aftertaste also has a sharp stimulus.

To increase the amount of heat transferred to the inside of beans, the

surface temperature of the beans, and thus the temperature of the air,

must be further increased. This is the reason why the air temperature is

as high as 200 ℃, which is why the hot air temperature control requires

experience.

Far-infrared rays are emitted from the surface of an object when it is

heated, pass through vacuum and air, and when it hits the object, the energy

of the far-infrared rays causes the molecules inside the object to resonate,

and the vibration causes frictional heat. The amount of heat proportional

to the amount of far infrared rays emitted moves toward the core of the

beans.

If the temperature of the beans does not reach 195℃, the aroma will be underdeveloped, and the taste will be astringent and

greenish. On the contrary, if the temperature exceeds 235 ℃, the aroma

will be burnt out, producing a burnt taste. (For more details, refer to

"Coffee Science" by Yukihiro Tanbe.) (Note: The temperature indicated

here is the temperature of the hot air type, not the temperature when parching

pan is used. Matsuda)

On the other hand, the far-infrared roasting profile measures the heat

generated by the beans, so the profile looks like the figure below.

|

After starting the roasting, take the time to dry the beans, and when they begin to turn brown, heating them to the temperature required for a favorable reaction, and when the roasting is nearing the end, determine the endpoint by taking time. Therefore, the profile is as shown on the right.

The temperature profile of the far-infrared method is more intuitive and

the temperature never exceeds 200 degrees Celsius. In my case, the temperature

above the opening of the roasting pan is at most 110 degrees. |

|

|

|

|

|

|